Starting with how to choose between metal and asphalt shingles, the discussion navigates through various aspects to help you make an informed decision.

From durability and cost considerations to maintenance requirements and environmental impacts, this guide covers everything you need to know.

Considerations for choosing between metal and asphalt shingles

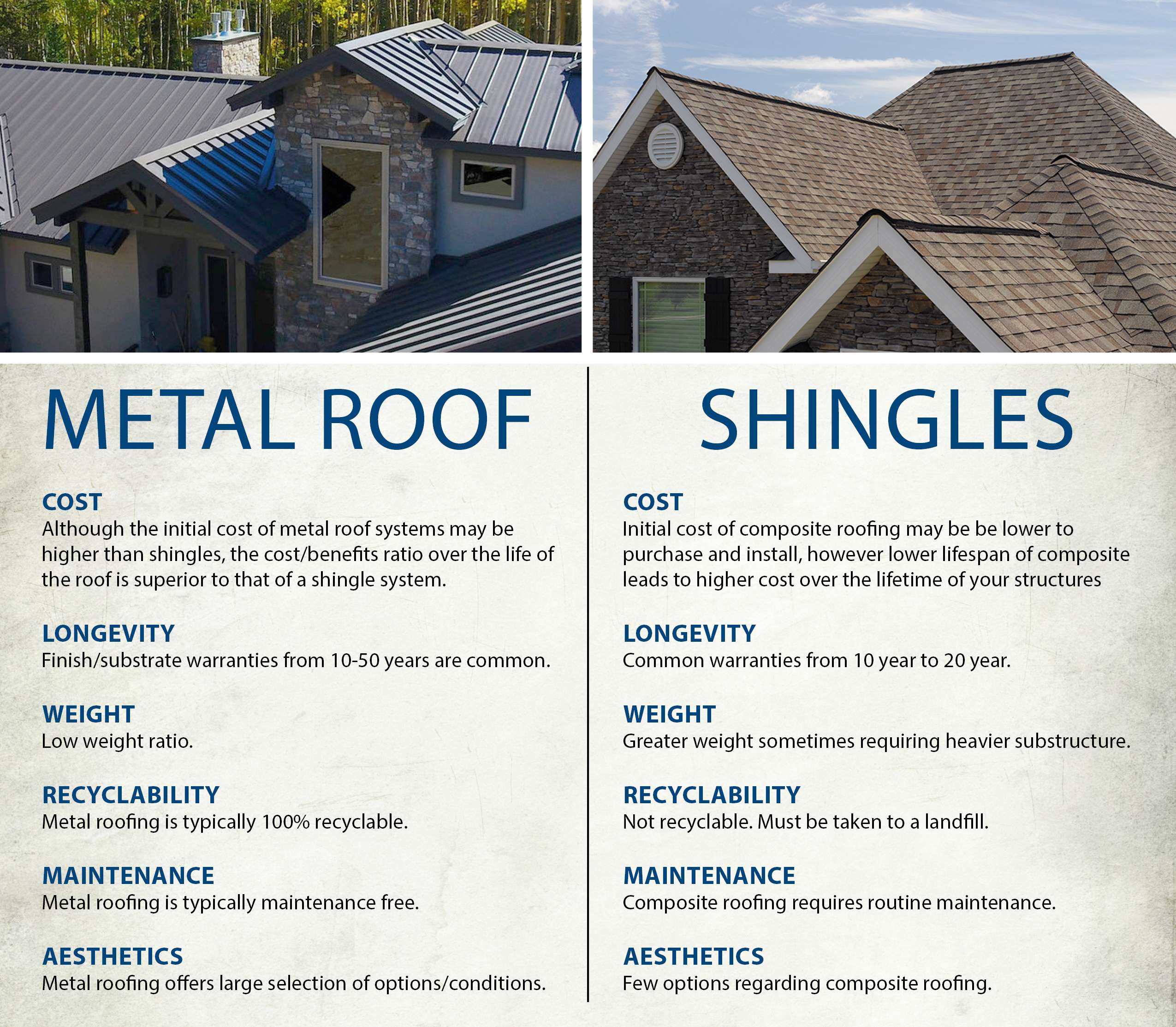

Metal and asphalt shingles are popular roofing materials, each with its own set of advantages and drawbacks. When deciding between the two, several key factors should be considered.

Compare the durability of metal and asphalt shingles

Metal shingles are known for their exceptional durability, often lasting 50 years or more. They are resistant to weather elements such as wind, rain, and snow. On the other hand, asphalt shingles have a shorter lifespan of around 20-30 years and may require more frequent repairs or replacements.

Discuss the cost differences between metal and asphalt shingles

Metal shingles are generally more expensive upfront compared to asphalt shingles. However, due to their longevity and low maintenance requirements, metal shingles may prove to be more cost-effective in the long run. Asphalt shingles are more affordable initially but may incur higher maintenance and replacement costs over time.

Identify the maintenance requirements for metal versus asphalt shingles

Metal shingles are low maintenance and require occasional inspections and cleanings. They are less prone to damage and deterioration compared to asphalt shingles, which may need regular inspections, repairs, and replacements to ensure longevity.

Analyze the environmental impact of metal and asphalt shingles

Metal shingles are considered more environmentally friendly than asphalt shingles. They are often made from recycled materials and are fully recyclable at the end of their lifespan. Asphalt shingles, on the other hand, contribute to landfill waste and are not easily recyclable. Additionally, metal shingles are energy-efficient and can help reduce heating and cooling costs in a home.

Durability of metal shingles

Metal shingles are known for their exceptional durability, making them a popular choice for homeowners looking for long-lasting roofing solutions.

Metal shingles typically have a lifespan of 40-70 years, depending on the type of metal used and the quality of installation. This far exceeds the average lifespan of asphalt shingles, which usually last around 20-30 years.

Performance in Extreme Weather Conditions

Metal shingles excel in extreme weather conditions such as heavy rain, snow, and high winds. They are highly resistant to moisture, preventing water damage and mold growth. Additionally, metal shingles are fire-resistant, providing an extra layer of protection for your home.

In areas prone to hurricanes, tornadoes, or hailstorms, metal shingles are a wise choice due to their ability to withstand such harsh weather conditions. Unlike asphalt shingles that can easily get damaged by strong winds or hail, metal shingles are more durable and can protect your home better in extreme situations.

Outperforming Asphalt Shingles

Metal shingles outperform asphalt shingles in terms of durability in various scenarios. For example, in regions with frequent temperature fluctuations, metal shingles are less likely to crack or warp compared to asphalt shingles. This makes them a more reliable choice for long-term protection against the elements.

Furthermore, metal shingles are less susceptible to damage from UV rays, which can cause asphalt shingles to deteriorate over time. With their superior resistance to fading and discoloration, metal shingles maintain their appearance and structural integrity for longer periods.

Overall, the durability of metal shingles makes them a cost-effective and low-maintenance roofing option, providing long-term protection and peace of mind for homeowners.

Durability of asphalt shingles

When it comes to the durability of roofing materials, asphalt shingles are a popular choice for many homeowners. Let’s explore how they compare to metal shingles in terms of longevity, common issues that can affect their durability, and how they hold up in harsh climates.

Longevity of Asphalt Shingles

- Asphalt shingles typically have a lifespan of 15 to 30 years, depending on the quality of the materials and the installation.

- Compared to metal shingles, asphalt shingles may not last as long, but they are more budget-friendly and easier to replace.

Common Issues Affecting Durability

- One common issue that can affect the durability of asphalt shingles is UV exposure, which can cause them to fade and deteriorate over time.

- Poor installation, inadequate ventilation, and extreme weather conditions can also contribute to premature wear and tear of asphalt shingles.

Durability in Harsh Climates

- Asphalt shingles can hold up well in harsh climates, such as areas with high winds, heavy rain, and snowfall, if properly installed and maintained.

- Choosing impact-resistant asphalt shingles and ensuring regular inspections and repairs can help increase their durability in challenging weather conditions.

Cost considerations when choosing between metal and asphalt shingles

Metal and asphalt shingles differ not only in terms of durability but also in cost implications. Understanding the cost breakdown and long-term financial impact can help you make an informed decision when choosing between the two materials.

Initial Cost of Installation

When it comes to the initial cost of installation, metal shingles tend to be more expensive than asphalt shingles. The price of metal shingles can vary significantly depending on the type of metal used, such as aluminum, steel, or copper. On the other hand, asphalt shingles are generally more affordable upfront, making them a popular choice for budget-conscious homeowners.

Long-term Cost Implications

While metal shingles may have a higher upfront cost, they are known for their longevity and durability. Metal roofs can last 50 years or more, while asphalt shingles typically have a lifespan of 20-30 years. This means that while you may pay more initially for metal shingles, you could save money in the long run by avoiding the need for frequent replacements or repairs.

Potential Cost Savings

One potential cost-saving benefit of metal shingles is their energy efficiency. Metal roofs reflect sunlight, helping to reduce cooling costs in the summer months. Additionally, metal shingles are resistant to mold, mildew, and rot, which can save you money on maintenance and repairs over time. On the other hand, asphalt shingles may require more frequent repairs and replacements, increasing your maintenance costs in the long term.

Maintenance requirements for metal shingles

Metal shingles are known for their durability, but they still require regular maintenance to ensure they last a long time and remain in top condition. Here are some key maintenance tasks needed for metal shingles and how they compare to asphalt shingles in terms of upkeep.

Maintenance tasks for metal shingles

- Regular inspections: Check for any signs of damage, loose shingles, or corrosion.

- Cleaning: Remove debris, dirt, and moss to prevent buildup and potential damage.

- Repairs: Promptly fix any damaged or loose shingles to prevent further issues.

- Coating: Apply a protective coating to enhance the shingles’ longevity and resistance to the elements.

Frequency of maintenance for metal shingles

Metal shingles generally require less frequent maintenance compared to asphalt shingles. While they are more durable and resistant to weather elements, it is still recommended to inspect and clean metal shingles at least once a year to prevent any issues from escalating.

Comparison of maintenance costs

When it comes to maintenance costs, metal shingles tend to be more cost-effective in the long run. While the initial installation cost may be higher than asphalt shingles, the minimal maintenance required for metal shingles can result in lower overall expenses over time. On the other hand, asphalt shingles may need more frequent repairs and replacements, leading to higher maintenance costs in the long term.

Maintenance requirements for asphalt shingles

When it comes to maintaining asphalt shingles, there are specific procedures that need to be followed to ensure their longevity and performance.

Asphalt shingles typically require maintenance every 3-5 years, which may involve tasks such as cleaning, inspecting for damage, and replacing any missing or worn-out shingles.

Comparison of maintenance efforts between asphalt shingles and metal shingles

- Asphalt shingles require more frequent maintenance compared to metal shingles, which can often last longer without needing repairs.

- Regular maintenance of asphalt shingles involves tasks like cleaning debris, checking for mold or mildew growth, and addressing any curling or cracking of shingles.

- Metal shingles, on the other hand, are more durable and resistant to weather elements, reducing the need for frequent maintenance.

- While asphalt shingles may be easier to repair or replace individually, the overall maintenance effort for metal shingles is generally lower over time.

Environmental impact of metal shingles

Metal shingles are considered to be eco-friendly roofing materials due to several factors that contribute to sustainability and environmental impact.

Metal shingles are sustainable because they are often made from recycled materials, such as aluminum or steel. This means that fewer raw materials are used in the production process, reducing the overall environmental footprint. Additionally, metal shingles are highly durable and have a long lifespan, which means they do not need to be replaced as frequently as other roofing materials. This longevity reduces waste and the need for constant manufacturing, further lowering the environmental impact.

Recycling options for metal shingles

Metal shingles are fully recyclable at the end of their lifespan, making them a more sustainable choice compared to asphalt shingles. Recycling metal shingles helps reduce the amount of waste sent to landfills and conserves valuable resources. Many metal roofing manufacturers offer recycling programs where old metal shingles can be collected and repurposed into new products, closing the recycling loop and minimizing environmental impact.

Environmental impact of asphalt shingles

When it comes to the environmental impact of asphalt shingles, there are several factors that need to be considered.

Analysis of environmental consequences

- Asphalt shingles are petroleum-based products, which means they contribute to the depletion of fossil fuels.

- The manufacturing process of asphalt shingles involves the release of harmful emissions and pollutants into the atmosphere.

- Disposal of asphalt shingles in landfills can lead to environmental pollution and potential harm to ecosystems.

Sustainability aspects of using asphalt shingles

- Asphalt shingles have a relatively short lifespan compared to other roofing materials, which means they need to be replaced more frequently, leading to increased waste generation.

- However, some manufacturers are incorporating recycled materials into their asphalt shingles, which can help reduce the environmental impact of production and disposal.

Eco-friendly alternatives or practices

- Opting for cool roof asphalt shingles, which are designed to reflect more sunlight and absorb less heat, can help reduce energy consumption and mitigate the urban heat island effect.

- Choosing asphalt shingles with a higher recycled content can also be a more sustainable option, as it reduces the demand for virgin materials.

Aesthetics and design considerations for metal and asphalt shingles

Metal and asphalt shingles differ not only in terms of durability and cost but also in aesthetics and design. The appearance of the shingles plays a crucial role in enhancing the overall look of a property. Let’s delve into the aesthetics and design considerations for metal and asphalt shingles.

Comparison of appearance

Metal shingles often provide a sleek and modern look to a property. They come in a variety of colors and finishes, including options that mimic the appearance of other materials such as wood or slate. On the other hand, asphalt shingles are more traditional and commonly seen in a range of colors, although they may not offer the same level of customization as metal shingles.

Versatility in design options

Metal shingles offer a high level of versatility in design options. They can be shaped and formed into different styles, allowing for unique and customized looks for a property. Asphalt shingles, while less versatile in terms of shape, still offer a wide range of design options in terms of color and texture.

Enhancing property aesthetics

Both metal and asphalt shingles can enhance the overall look of a property when chosen carefully. Metal shingles, with their modern appearance and customization options, can add a contemporary touch to a property. On the other hand, asphalt shingles provide a more classic look that can complement a wide range of architectural styles. The choice between metal and asphalt shingles ultimately depends on the desired aesthetic impact and design preferences of the property owner.

Installation Process and Complexity of Metal and Asphalt Shingles

When considering the installation of roofing materials, it is essential to understand the process and complexity involved. Metal and asphalt shingles have distinct installation methods that require different levels of expertise.

Metal Shingles Installation

Metal shingles are typically installed in the following steps:

- Prepare the roof deck by ensuring it is clean, dry, and free of any debris.

- Install underlayment to provide an extra layer of protection against water infiltration.

- Begin laying the metal shingles from the bottom of the roof, overlapping each panel to ensure a watertight seal.

- Secure the shingles in place using screws or nails, following the manufacturer’s guidelines.

- Finish the installation with ridge caps to seal the peak of the roof and complete the look.

The installation of metal shingles requires a moderate to high level of expertise, as it involves precise measurements, cutting, and fastening techniques. It is recommended to hire professional roofers with experience in working with metal roofing materials.

Asphalt Shingles Installation

The installation process for asphalt shingles is as follows:

- Prepare the roof deck by inspecting for any damage and ensuring it is structurally sound.

- Install a layer of underlayment to protect against moisture and provide additional insulation.

- Begin laying the asphalt shingles from the bottom of the roof, overlapping each row to prevent water penetration.

- Secure the shingles with nails and follow the manufacturer’s instructions for proper placement.

- Finish the installation by adding ridge caps to the roof peak for a clean and finished appearance.

Compared to metal shingles, the installation of asphalt shingles is considered less complex and can be done by experienced DIY enthusiasts. However, for optimal results and warranty compliance, it is recommended to hire professional roofers for asphalt shingle installation.

Ultimate Conclusion

In conclusion, whether you prioritize longevity, cost-effectiveness, or eco-friendliness, understanding the differences between metal and asphalt shingles is crucial in selecting the right option for your roofing needs.